D5 Solar

The first DC spherical motor pump for

directconnection to photovoltaic panels with automatic performance

optimization using MPP technology (Maximum Power Point tracking)

Application

The Ecocirc solar pump can be used wherever a highly efficient

circulation pump is needed without a direct connection to AC power. It

can be connected directly to a photovoltaic panel and is characterized

by its small size, high efficiency, very low power consumption and its

MPP tracking. The shaftless spherical motor

technology enables a long, maintenance free and quiet service life.

Areas of application are thermal solar systems for single family homes.

Design

The principle of the spherical motor, which was invented by Laing, is

fundamentally different from conventional canned motor pumps. The only

moving part in a spherical motor is a hemispherical rotor/impeller

unit, which sits on an ultra-hard, wear-resistant ceramic ball. There

are no conventional shaft bearings or seals. This rules out, in effect,

the possibility of play in the bearings and the increase in noise

associated with it. These pumps are particularly robust and give

exceptionally long service. The self-realigning bearing is lubricated

and cooled by the media. Maintenance is not necessary under normal

conditions and even after lengthy shutdown periods a reliable start-up

is virtually guaranteed. The parts exposed to the fluid are completely

corrosion resistant.

Soft start-up

The pump has been programmed for a soft start-up. When the photovoltaic

panel provides sufficient power, the pump first goes through the

alignment phase, turning the rotor into the position required for

start-up. Then the processor waits until the built-in capacitor has

recharged sufficiently. This enables a start-up with minimal power

(less than one Watt). Cycling due to unsuccessful starting attempts is

minimized. Even after prolonged shutdown, the pump will start reliably.

Automatic performance optimization – MPP tracking

The Ecocirc DC pumps are the first and only spherical motor pumps with

self-optimizing software (see diagram). Every three seconds, the

processor will modify its operating point on the voltage-current curve

of the PV panel to find the point of maximum performance. This is

called the “Maximum Power Point” (MPP).

At this point, the pump achieves the maximum rpm and therefore the

maximum performance. There is no need for a separate performance

adaptation, the pump will always find its best operating point under

any given light and temperature conditions by itself.

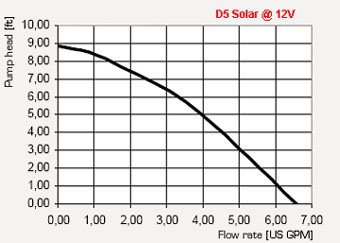

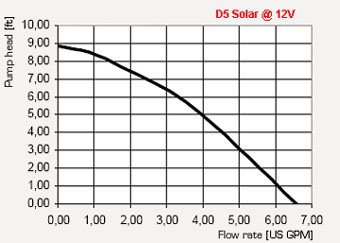

Pump Curve

|

Technical Data

-

Motor design: Electronically commutated,

spherical motor

-

Voltage Range: 8 to 24 V DC

-

Maximum system pressure: 150 PSI (brass

housing), 50 PSI (plastic housing)

-

Maximum Temperature: 230°F (brass),

140°F (plastic)

-

Acceptable media: Domestic hot water, heating

water, water/Glycol mixtures and other media on request.

Pump Housing

|

|

Common Applications

-

Solar systems

-

Computer cooling

systems

-

Circulating

systems for homes, RV’s and boats

-

Engine block

circulating systems

-

Juice machines

-

Aquariums and

ponds

-

Oxygen generating

systems

-

Vending machines

-

Water fountains

-

Process

temperature control

-

Remote area fluid

handling

Snap-out Design

Snap-out design of

motor drive unit permits motor replacement without draining the pump’s

fluid. No special tools required. The DC motor can easily be swapped

with an AC motor.

|

| Model |

Housing design |

Connection

|

Shipping |

| No. |

|

|

Weight |

D5

Bronze Series (8-24V DC, 3-35 Watts, 0.30-1.50

Amps) 230° F

|

| D5 solar 720 B |

Inline |

1/2’’ sweat connection

|

3.0

|

D5 solar 710 B

|

Inline

|

1/2’’ female pipe thread

|

|

| D5 solar 090 B |

Inline / BV+CV+PV*

|

1/2’’ union sweat

|

3.0

|

D5

Plastic/Stainless Steel Series (8-24V DC, 3-35 Watts,

0.30-1.50 Amps) 140° F

|

| D5 solar 850 N |

Angled housing |

1/2"

male thread |

2.0

|

| D5 solar 810

N |

Angled housing

|

1/2"

hose barb |

2.0

|

| D5 solar 790

N |

Angled housing

|

3/4"

hose barb |

2.0

|

EcoVantage Mobile Catalog

EcoVantage Mobile Catalog